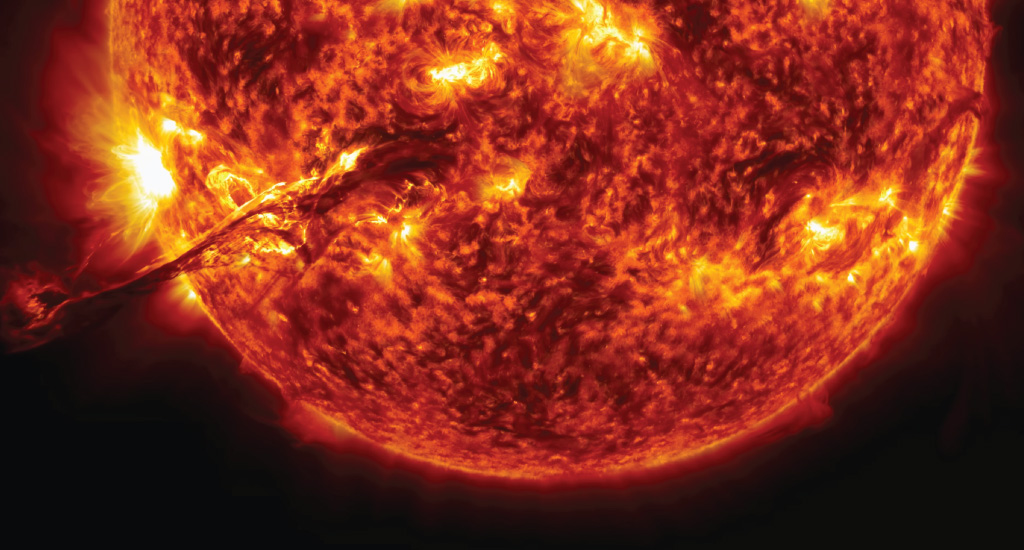

The most complex scientific laboratory ever to have been sent to study the Sun, the European Space Agency (ESA) Solar Orbiter is overcoming the immense technical challenges of close orbit to return exciting data about the origins and nature of our star.

On a seven-year mission that launched in February 2020, ESA scientists hope to answer some profound questions about the Sun’s 11-year cycle of magnetic activity, the Sun’s heating processes, the origins of the solar wind and how solar activity affects our planet.

Passing within 42 million kilometres of our life-giving star, the orbiter’s six remote-sensing instruments and four in-situ instruments began routine science operations in November 2021. The Solar Orbiter has already obtained compelling data as to the origin of magnetic switchbacks, pointing towards how they might accelerate the solar wind, and captured the first-ever close-up images of the Sun’s polar regions and views of the transit of Mercury.

But this feat has not been simple to achieve.

The Solar Orbiter experiences levels of sunlight thirteen times higher than satellites orbiting the Earth, enduring powerful bursts of atomic particles from explosions in the Sun’s atmosphere. It has required close international collaboration and exceptional technical ingenuity to build a craft capable of protecting itself and its payload of precision instruments from high temperatures and searing conditions.

A vital part of the propulsion system

Solar Orbiter builds on a long tradition of European-lead Sun exploration, including Helios 1 and 2, Ulysses, and SOHO. These were developed in partnership with the National Aeronautics and Space Administration (NASA), which provided the launcher for the project and contributed instruments to the scientific payload.

The contract to build Solar Orbiter was awarded to Astrium UK, which spearheaded a team of global suppliers to manufacture the craft. This included OHB Sweden, a provider of complete space missions, satellites and spacecraft subsystems.

Source: ASTRIUM

On its journey to the Sun, Solar Orbiter used gravity assists from Venus and Earth in a series of complex manoeuvres that relied on the craft’s Attitude and Orbit Control Subsystem (AOCS) and the Solar Orbiter’s Chemical Propulsion System (CPS). This put the craft into orbit around the Sun, along which reaches its closest point to the star every five months. At its highest speed, it reaches an almost stationary orbit, allowing unprecedented observations to be made.

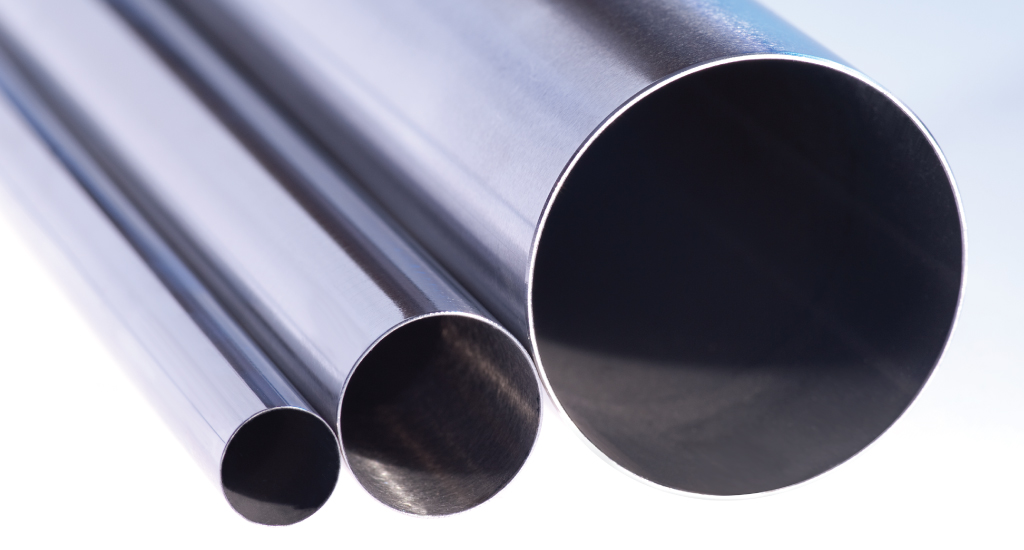

As the Orbiter’s Chemical Propulsion System (CPS) required durable, high-precision tubing to function, OHB Sweden contracted Fine Tubes to manufacture significant volumes of titanium tubing Grade 9. Fine Tubes was selected on the proven record of providing high quality, precision tubes, manufactured to the tightest specifications to ensure performance without failure in the most critical applications.

Meeting the challenges of solar exploration

The Solar Orbiter’s performance depends entirely on being able to resist the high temperatures and energies generated by the Sun. In particular, the high-energy bursts known as Coronal Mass Ejections can disrupt satellite communications and electrical power distribution systems, as well as cause computers to crash. The data provided by Solar Orbiter will enable scientists to better understand what causes these violent and disruptive phenomena.

Being close to these solar events means the Solar Orbiter requires high-level protection against the harsh environments and extreme 500°C temperatures encountered during 22 orbits of the sun.

This challenging environment in which the titanium tubes operate meant that traditional manufacturing processes had to be improved to meet demanding technical specifications.

However Fine Tubes’ expertise in adapting precision manufacturing processes to specific customer requirements means existing aerospace technologies have been developed to meet the key needs of space operations: exceptional cleanliness, survivability in a hostile environment, and a zero-maintenance design.

Applying aerospace expertise to space travel

The ability to innovate is critical to the aerospace industry. A principal driver for manufacturers is developing new materials that meet higher performance requirements while reducing weight and cost. Correspondingly, Fine Tubes engineers and metallurgists work alongside customers to develop custom-made tube solutions that meet their individual application needs while hitting these demanding production drivers.

Titanium was selected as the main alloy for the Solar Orbiter due to its advantageous strength-to-weight ratio.

For space applications, where customer and performance demands are greatest, Fine Tubes uses seamless titanium tubes (Ti3/2.5V) – an established aerospace material. For Solar Orbiter, the company used its expertise to develop higher strength-to-weight titanium alloys that retained essential cold workability. Fine Tubes supplied Grade 9 tubing manufactured to the small sizes required, using processes that met the most stringent cleanliness requirements.

This assisted the Solar Orbiter to optimize its design and meet precise weight restraints with a launch mass of just 1720kg; while the strength and resilience of the material gave designers full confidence in performance – critical where there is no option or prospect of repair.

With the mission proceeding successfully, the Solar Orbiter is expected to continue to yield new secrets of the sun until the end of the mission in December 2026, after which it is hoped an extended mission can begin.

As of 2023 the mission has encountered no operational issues and continues to produce new insights: a testament to all involved in creating such a high-precision feat of engineering, operating at the limits of current technology.

Find out more about our precision tubing solutions https://www.finetubes.co.uk/markets/space-and-satellites